Construction Techniques : Bulding circuits with linoleum cutter and magnet wire

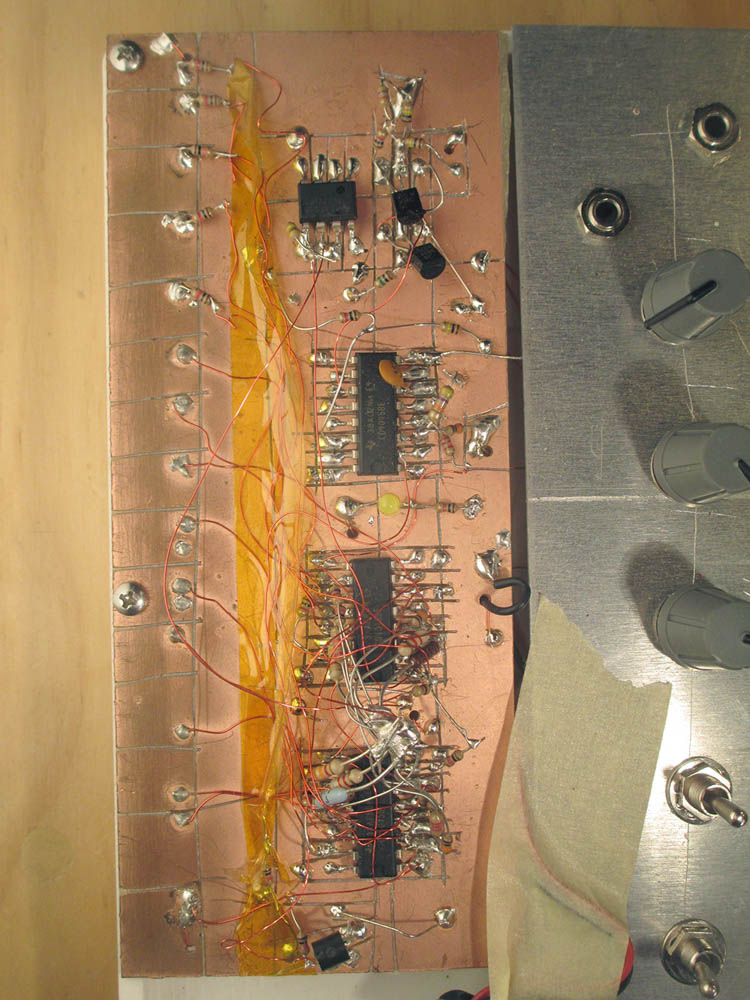

-- a prototype technique idea here -- Like everyone I mostly use a breadboard, but recently in the mood to be soldering and really building an object with some life beyond the temporary. I will just note here The artworks, cartoons, and engineering of Jim Williams as an overall inspiration, but especially for these construction techniques. So I use an art printing block cutter to cut board traces sometimes. The kind with plastic handle and replaceable blades for linoleum. Using this technique I'm cutting with much more ease than cutting with a utility knife. I use the deep sturdy v cutting blade to remove a good width of copper so to be sure I wont easily bridge the planes. I mostly use FR1 (paper and phenolic resin with copper on one side) from the internet rather than FR4 fiberglass for the sake of keeping the blades sharper longer, its easier to cut, and its also less toxic.

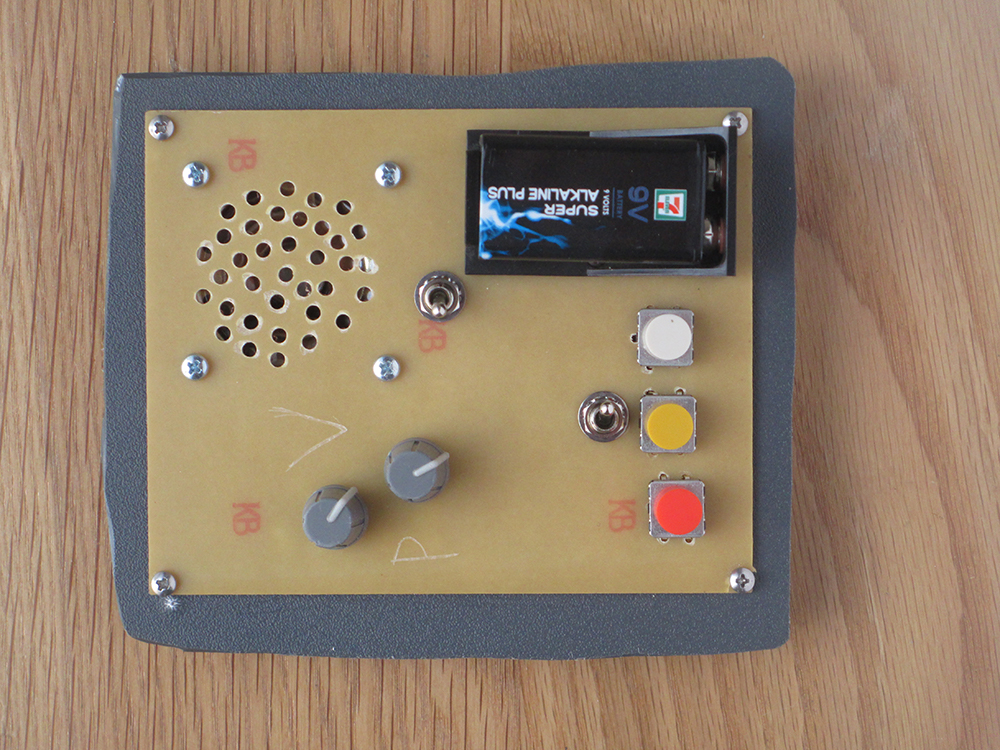

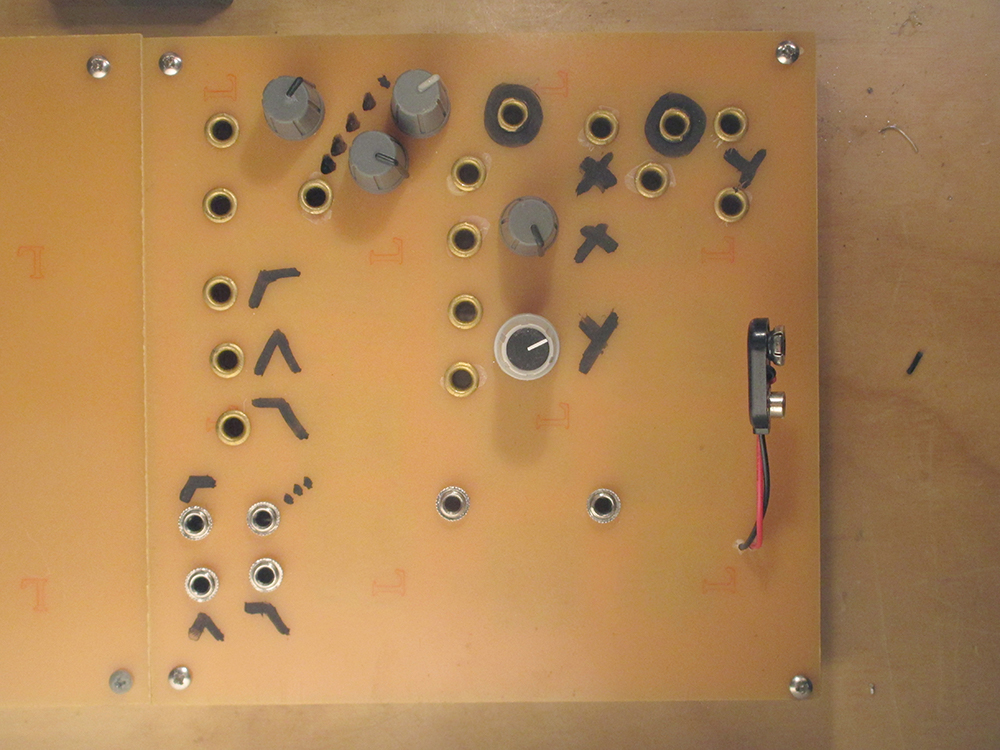

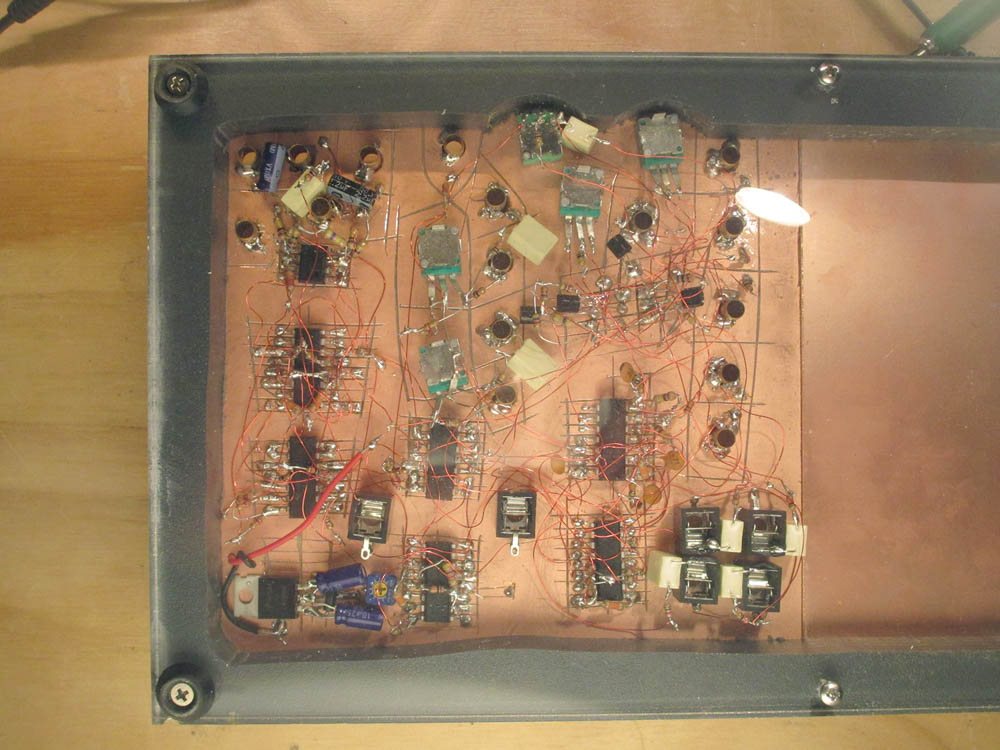

-- a prototype technique idea here -- Like everyone I mostly use a breadboard, but recently in the mood to be soldering and really building an object with some life beyond the temporary. I will just note here The artworks, cartoons, and engineering of Jim Williams as an overall inspiration, but especially for these construction techniques. So I use an art printing block cutter to cut board traces sometimes. The kind with plastic handle and replaceable blades for linoleum. Using this technique I'm cutting with much more ease than cutting with a utility knife. I use the deep sturdy v cutting blade to remove a good width of copper so to be sure I wont easily bridge the planes. I mostly use FR1 (paper and phenolic resin with copper on one side) from the internet rather than FR4 fiberglass for the sake of keeping the blades sharper longer, its easier to cut, and its also less toxic.  Also I sometimes end up making panel for and out of the proto circuit by just drilling and mounting pots with the nut and then soldering to the legs. A single plane with all of the components and dials and plugs floating on and through it as the panel and circuit plane. Bananas can be the 5mm brass grommets which fit the 4mm banana plugs well! overall I have been enjoying this as an easy proto/quick fab technique. allows a non linear work-flow like -- cut some traces then solder some components then cut some more and try something else... its more freeing to me than breadboard also I can tell better what is and isnt connected! it can be hard to track down bad breadboard slots.

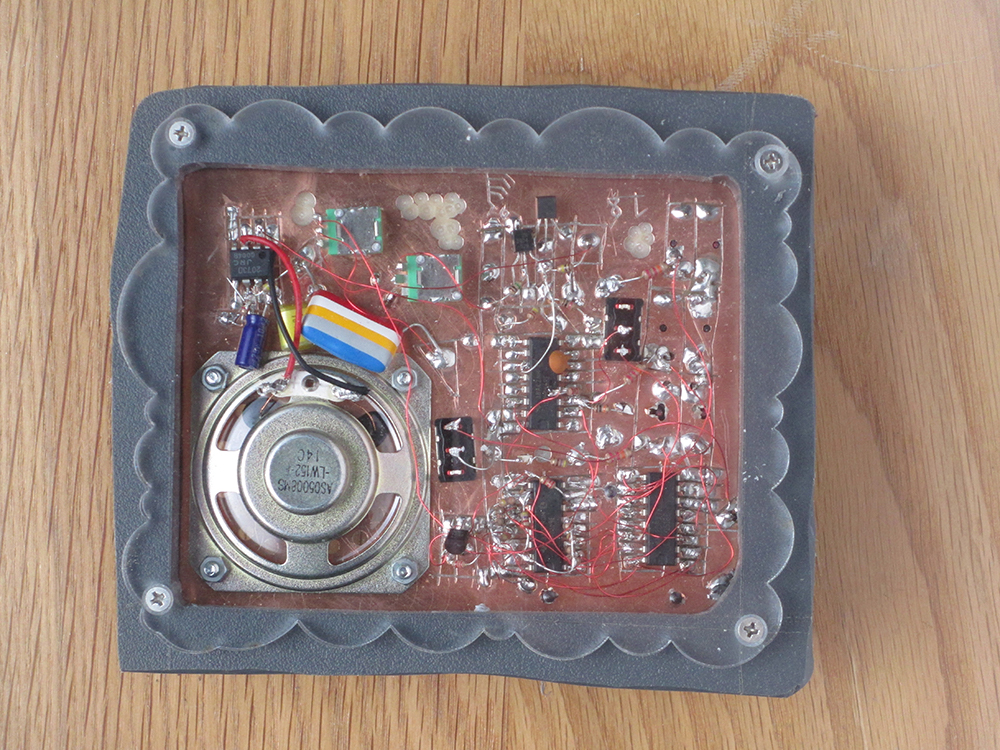

Also I sometimes end up making panel for and out of the proto circuit by just drilling and mounting pots with the nut and then soldering to the legs. A single plane with all of the components and dials and plugs floating on and through it as the panel and circuit plane. Bananas can be the 5mm brass grommets which fit the 4mm banana plugs well! overall I have been enjoying this as an easy proto/quick fab technique. allows a non linear work-flow like -- cut some traces then solder some components then cut some more and try something else... its more freeing to me than breadboard also I can tell better what is and isnt connected! it can be hard to track down bad breadboard slots. I use mostly magnet wire to jump, of a gauge like 30 -- easy to tin with just the soldering iron and it just goes on there solder it up. There is an enamel coating which covers the wire and it is easily removed by just tinning the end of the wire. It also makes it easier to remove the coating in the middle of the wire without stripping it or cutting it. This way of using magnet wire comes from Elm Chan. These pictures should be instructive. I like the way this technique allows me to wander and think as I work. More thoughts and developments to come soon, hopefully some on the HDPE recycling/injection molder idea.

I use mostly magnet wire to jump, of a gauge like 30 -- easy to tin with just the soldering iron and it just goes on there solder it up. There is an enamel coating which covers the wire and it is easily removed by just tinning the end of the wire. It also makes it easier to remove the coating in the middle of the wire without stripping it or cutting it. This way of using magnet wire comes from Elm Chan. These pictures should be instructive. I like the way this technique allows me to wander and think as I work. More thoughts and developments to come soon, hopefully some on the HDPE recycling/injection molder idea.